Types and Features of Surface Mount Cabinet Door Locks

Surface mount cabinet door locks offer a convenient and versatile solution for securing cabinets and drawers in various settings, from homes and offices to industrial environments. Their ease of installation and wide range of styles and security levels make them a popular choice for both DIY enthusiasts and professional installers. Let’s delve into the specifics of these practical and adaptable locking mechanisms.

Surface Mount Cabinet Door Lock Mechanisms: A Comparison

Choosing the right surface mount cabinet lock depends on your specific needs and the level of security required. The following table provides a detailed comparison of different mechanisms, highlighting their strengths and weaknesses.

| Type | Material | Security Level | Installation Difficulty |

|---|---|---|---|

| Cam Lock | Metal (usually zinc alloy or steel) | Low to Medium (easily defeated with simple tools) | Easy |

| Magnetic Latch | Metal (various alloys), Plastic | Low (easily opened with a strong magnet) | Very Easy |

| Push Button Lock | Metal (various alloys), Plastic | Low to Medium (depends on the mechanism complexity) | Easy to Medium |

| Hasp and Staple Lock | Metal (usually steel) | Medium to High (requires a padlock for additional security) | Medium |

| Combination Lock | Metal (various alloys) | Medium to High (difficulty depends on the number of combinations) | Medium |

Features of Surface Mount Cabinet Door Locks

A wide array of features enhances the functionality and security of surface mount cabinet locks. Understanding these features is crucial for selecting the perfect lock for your application.

Surface mount cabinet door locks – Here are some key features to consider:

- Key Types: These range from simple keyed locks to more complex keyed alike or keyed different systems. Keyed alike systems allow multiple locks to be opened with the same key, while keyed different systems use unique keys for each lock. This choice depends on your need for master key systems or individual access control.

- Locking Mechanisms: Different mechanisms offer varying levels of security. Cam locks use a rotating cam to engage with the strike plate, while magnetic latches use magnetic force for a simple closure. Hasp and staple locks offer higher security as they require a separate padlock.

- Security Features: Some locks incorporate features like reinforced housings, tamper-resistant mechanisms, or pick-resistant cylinders to deter unauthorized access. Consider these features for higher-security applications.

- Finish Options: Surface mount locks are available in a variety of finishes, including chrome, nickel, brass, and black, allowing for seamless integration with your cabinetry.

Compatibility of Surface Mount Cabinet Locks with Cabinet Materials

Choosing a compatible lock is essential for proper function and longevity. The following table Artikels the compatibility of various surface mount lock types with different cabinet materials.

| Lock Type | Cabinet Material | Compatibility Notes |

|---|---|---|

| Cam Lock | Wood, Metal, Plastic | Generally compatible with most materials; ensure proper mounting hardware is used. |

| Magnetic Latch | Wood, Metal, Plastic | May require adhesive backing for certain materials. Ensure sufficient magnetic force for secure closure. |

| Push Button Lock | Wood, Metal, Plastic | Ensure proper alignment and sufficient mounting depth. |

| Hasp and Staple Lock | Wood, Metal | Requires drilling for mounting. Metal cabinets may require specialized screws. |

| Combination Lock | Wood, Metal | Requires sufficient mounting depth and strength. |

| All Types | Glass | Requires specialized mounting hardware and may necessitate additional reinforcement. |

Installation and Maintenance of Surface Mount Cabinet Door Locks

Installing and maintaining surface mount cabinet door locks is a straightforward process that can significantly enhance the security and longevity of your cabinets. Proper installation ensures a secure fit and prevents easy access, while regular maintenance prevents wear and tear, extending the life of your locks. Let’s dive into the specifics!

Step-by-Step Installation Procedure

Before you begin, gather the necessary tools and take appropriate safety precautions. This will ensure a smooth and safe installation process. The following steps provide a clear guide for installing your new lock.

- Gather Tools and Materials: You’ll need a screwdriver (likely Phillips head), a pencil, a measuring tape, and possibly a drill with the appropriate drill bit (depending on the lock and cabinet material). Also, ensure you have the lock, mounting hardware (screws), and any included instructions.

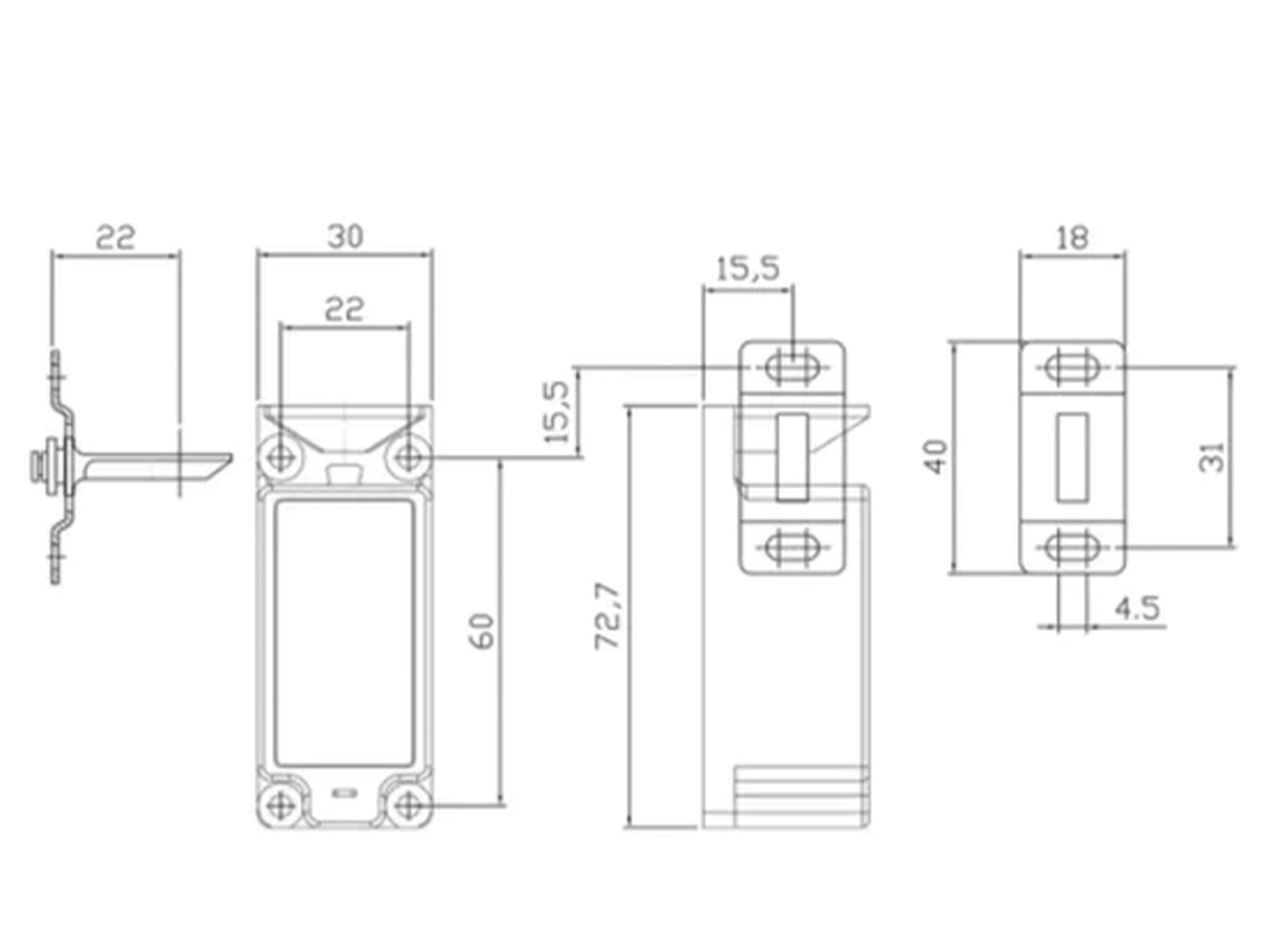

- Plan Placement: Use a pencil to carefully mark the desired location for the lock on the cabinet door. Consider the door’s thickness and the lock’s dimensions to ensure proper alignment and clearance.

- Pre-Drill (If Necessary): If your cabinet is made of a hard material like hardwood, pre-drilling pilot holes will prevent the wood from splitting when you insert the screws. Use a drill bit slightly smaller than the diameter of your screws.

- Attach the Lock Body: Align the lock body with your marked location and secure it to the door using the provided screws. Ensure the lock is flush with the door’s surface.

- Install the Latch: Install the latch mechanism into the cabinet frame, ensuring it aligns correctly with the lock body. This often involves drilling pilot holes and securing the latch with screws.

- Test the Lock: Once everything is secured, test the lock to ensure it engages and disengages smoothly. Adjust the placement if necessary for optimal function.

Best Practices for Maintenance, Surface mount cabinet door locks

Regular maintenance is crucial for extending the lifespan of your surface mount cabinet locks and ensuring they continue to function reliably. These simple steps will help keep your locks in top condition.

- Regular Cleaning: Periodically clean the lock mechanism with a soft cloth and mild cleaner. This removes dust and debris that can hinder its operation.

- Lubrication: Apply a small amount of lubricant (like WD-40 or a silicone-based lubricant) to the moving parts of the lock to reduce friction and prevent wear. Avoid excessive lubrication.

- Tighten Screws: Check the screws periodically and tighten them if they become loose. Loose screws can lead to misalignment and malfunction.

- Inspect for Damage: Regularly inspect the lock for any signs of damage, such as cracks, bends, or broken parts. Replace the lock if necessary.

Troubleshooting Common Problems

During installation or maintenance, you may encounter some common issues. Understanding these problems and their solutions will help you resolve them quickly and efficiently.

Problem 1: The lock doesn’t latch properly. This could be due to misalignment of the lock body and latch, loose screws, or debris obstructing the mechanism. Carefully check the alignment, tighten any loose screws, and clean any debris from the mechanism. If the problem persists, you may need to adjust the latch position slightly.

Problem 2: The lock is difficult to turn. This is often caused by lack of lubrication or accumulated dirt and grime. Apply a small amount of lubricant to the moving parts and clean the lock mechanism thoroughly. If the problem persists, there might be internal damage requiring replacement.

Problem 3: The lock is loose or wobbly. This usually indicates loose screws. Tighten all screws securely, ensuring the lock is firmly attached to the door and frame. If the problem persists, the mounting holes might be stripped, requiring repair or replacement.

Problem 4: The key doesn’t turn smoothly. This often points to a problem with the key itself, or the internal mechanism. Try using a different key (if applicable). If the issue persists, there may be debris blocking the mechanism, requiring thorough cleaning. If cleaning doesn’t resolve the problem, the lock may need replacement.

Applications and Security Considerations of Surface Mount Cabinet Door Locks

Surface mount cabinet locks offer a versatile and readily accessible security solution for a wide range of applications. Their ease of installation and diverse locking mechanisms make them a popular choice across various sectors, each with specific security needs and considerations. Understanding these applications and potential vulnerabilities is crucial for selecting the right lock and implementing effective security measures.

The following table illustrates the diverse applications of surface mount cabinet locks, highlighting the specific lock types, security needs, and advantages in different settings.

| Setting | Lock Type | Security Needs | Advantages |

|---|---|---|---|

| Residential (Kitchen Cabinets) | Cam Lock, Push-Button Lock | Childproofing, preventing accidental access | Easy installation, affordable, various finishes to match décor |

| Commercial (Office Supply Closets) | Key Lock, Combination Lock | Protecting sensitive documents, preventing unauthorized access to inventory | Increased security compared to residential options, key control management possible |

| Industrial (Chemical Storage Cabinets) | Padlock Hasp, keyed locking mechanism with high security rating | Preventing unauthorized access to hazardous materials, compliance with safety regulations | Robust construction, ability to accommodate heavy-duty padlocks, tamper-resistant designs |

| Healthcare (Medication Cabinets) | Key Lock, Electronic Lock with Audit Trail | Controlled substance management, maintaining accurate medication records | High security, ability to track access, compliance with regulatory requirements |

Security Implications and Countermeasures

While surface mount cabinet locks provide a degree of security, understanding their potential vulnerabilities is crucial for effective security implementation. Ignoring these vulnerabilities can lead to compromised security and potential losses.

- Vulnerability to forceful entry: Surface mount locks are susceptible to forceful attacks, particularly if the cabinet material is weak or the lock is poorly installed. Countermeasure: Use robust cabinet materials and install the lock securely.

- Picking or manipulation: Simpler lock mechanisms can be picked or manipulated with tools. Countermeasure: Choose locks with higher security ratings and complex mechanisms, such as those with multiple locking points or anti-picking features.

- Key duplication or loss: Lost or stolen keys can compromise security. Countermeasure: Use high-security keys, implement key control systems, and consider locks with changeable combinations.

- Tampering and vandalism: Locks can be tampered with or damaged intentionally. Countermeasure: Select locks with tamper-resistant features, consider using security seals, and implement surveillance measures.